LiNbO3

LiNbO Crystal is widely used as frequency doublers for wavelength 1 m and optical parametric oscillators (OPOs) pumped at 1064nm as well as quasi-phase-matched (QPM) devices. Due to its large Electro..

ProductsOptical CrystalBirefringent CrystalLiNbO3

LiNbO3

LiNbO Crystal is widely used as frequency doublers for wavelength > 1 m and optical parametric oscillators (OPOs) pumped at 1064nm as well as quasi-phase-matched (QPM) devices. Due to its large Electro-Optic ((E-O) and Acousto-Optic (A-O) coefficient, LiNbO crystal is the most commonly used material for Pockel Cells, Q-switches and phase modulators, waveguide substrate, and surface acoustic wave (SAW) wafers, etc.

LiNbO Crystal is widely used as frequency doublers for wavelength > 1 m and optical parametric oscillators (OPOs) pumped at 1064nm as well as quasi-phase-matched (QPM) devices. Due to its large Electro-Optic ((E-O) and Acousto-Optic (A-O) coefficient, LiNbO crystal is the most commonly used material for Pockel Cells, Q-switches and phase modulators, waveguide substrate, and surface acoustic wave (SAW) wafers, etc.

Basic Properties:

|

Crystal Structure

|

Trigonal, space group R 3c

|

|

Cell Parameters

|

a = 0.515, c = 13.863, Z = 6

|

|

Melting Point

|

1255 +/-5℃

|

|

Curie Point

|

1140 +/-5℃

|

|

Mohs Hardness

|

5

|

|

Density

|

4.64 g/cm 3

|

|

Absorption Coefficient

|

~ 0.1%/cm @ 1064 nm

|

|

Solubility:

|

insoluble in H 2 O

|

|

Relative Dielectric Constant

|

ε T11/ε 0 : 85

|

|

ε T33/ε 0 : 29.5

|

|

|

Thermal Expansion Coefficients at 25℃

|

||a, 2.0 x 10 -6 /K @ 25℃

|

|

||c, 2.2 x 10 -6 /K @ 25℃

|

|

|

Thermal Conductivity

|

38 W /m /K @ 25℃

|

|

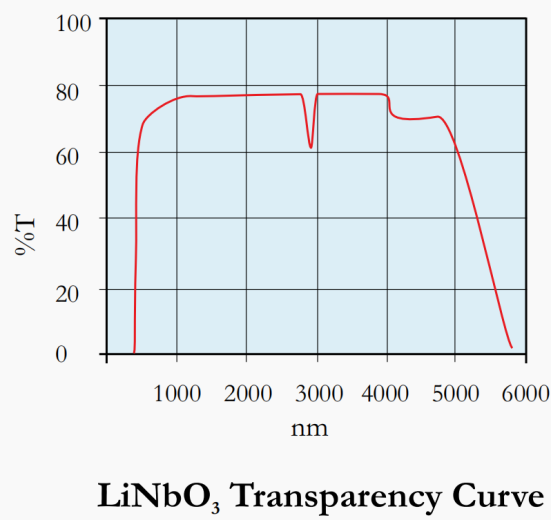

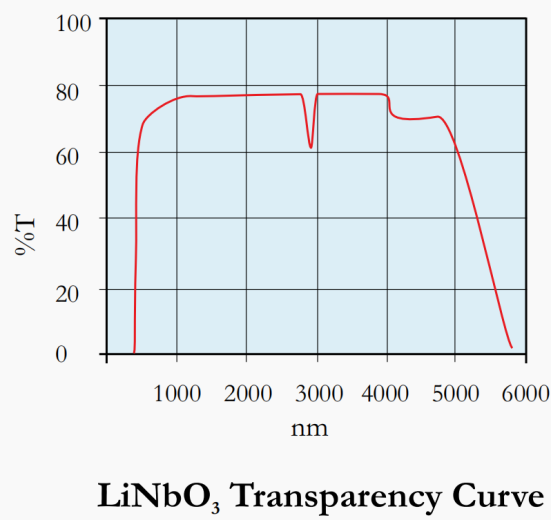

Transparency Range

|

420 - 5200 nm

|

|

Refractive Indices

|

n e = 2.146, n o = 2.220 @ 1300 nm

|

|

n e = 2.156, n o = 2.322 @ 1064 nm

|

|

|

n e = 2.203, n o = 2.286 @ 632.8 m

|

|

|

Optical Homogeneity

|

~ 5 x 10 -5 /cm

|

|

Sellmeier Equations( l in mm)

|

n o 2 (l) = 4.9048+0.11768/(l2- 0.04750) - 0.027169l2

|

|

n e 2 (l) = 4.5820+0.099169/( l2 - 0.04443) - 0.021950 l2

|

|

|

NLO Coefficients

|

d 33 = 34.4 pm/V

|

|

d 31 = d 15 = 5.95 pm/V

|

|

|

d 22 = 3.07 pm/V

|

|

|

Electro-Optic Coefficients

|

γT 33 = 32 pm/V, γS 33 = 31 pm/V

|

|

γ T 31 = 10 pm/V, γ S 31 = 8.6 pm/V

|

|

|

γ T 22 = 6.8 pm/V, γS 22 = 3.4 pm/V,

|

|

|

Half-Wave Voltage, DC

|

3.03 KV

4.02 KV

|

|

Electrical field ||z, light ^ z:

|

|

|

Electrical field ||x or y, light || z:

|

|

|

Damage Threshold

|

200 MW/cm 2 (10 ns)

|

|

Efficiency NLO Coefficients

|

d eff =5.7pm/V or~14.6xd 36 (KDP) for frequency doubling 1300 nm;

|

|

d eff =5.3pm/V or~13.6xd 36 (KDP) for OPO pumped at 1064nm;

|

|

|

d eff =17.6pm/V or~45xd 36 (KDP) for quasi-phase-matched structure;

|

|

Flatness

|

λ/8 @ 632.8nm

|

|

Wavefront distortion

|

<λ/4@ 632.8nm

|

|

Surface quality

|

10/5 per MIL-O-13830A

|

|

Parallelism

|

10″

|

|

Perpendicularity

|

5′

|

|

Bevel/chamfer

|

<0.1mm@45deg.

|

|

Chips

|

<0.1mm

|

|

Angle Tolerance

|

△θ≤±0.5°, △φ≤±0.5°

|

|

Coating

|

AR/P- coating Upon request

|

Note: OEM Dimension, different axis angle cutting and coating and damage threshold upon request, others are available upon request.